Description

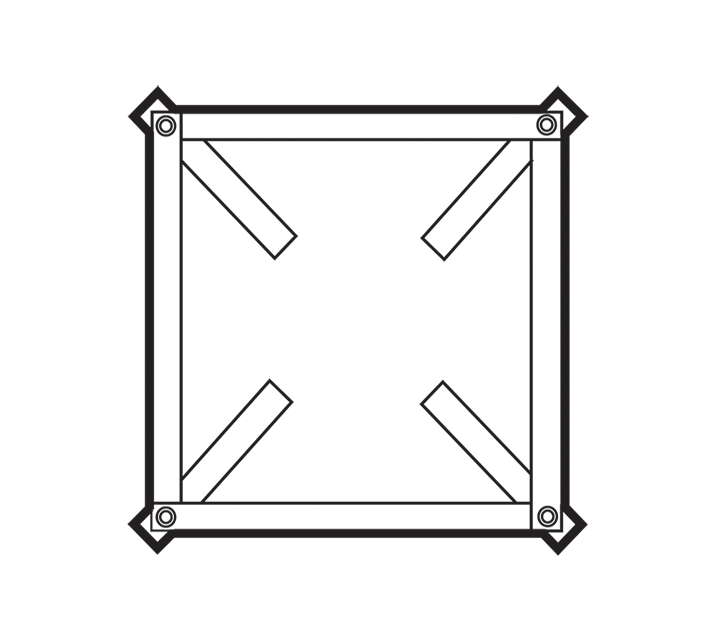

• Base manufactured from phosphated pressed steel, epoxy powder coated with hammered effect finish, guaranteeing long-term resistance to atmospheric agents.

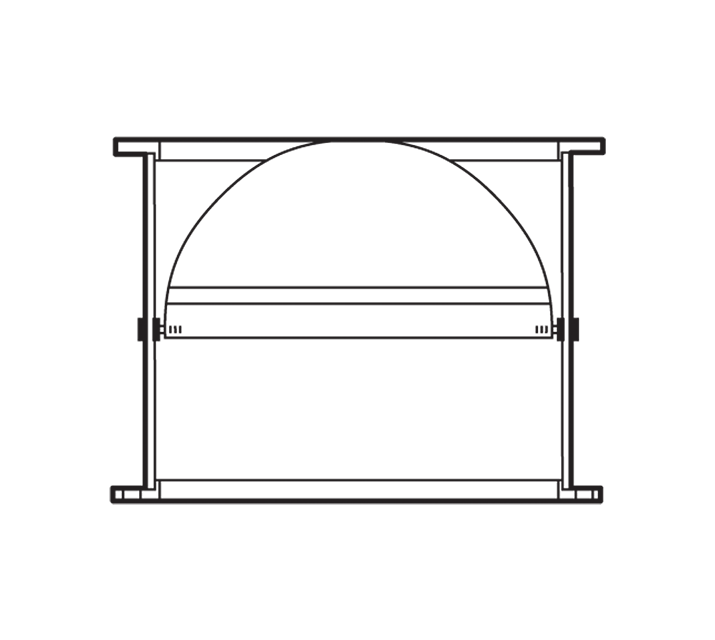

• Aerodynamically contoured inlet port for optimum performance, fashioned as a single unit with the base and gauged to optimize air flow.

• Pressed steel motor cover: pickled and phosphated surface, polyester powder coated and oven baked finish, colour grey, with hammered texture.

• Pressed steel side baffles angled to exhaust extracted air upwards: zinc-coated, pickled and phosphated surface, polyester powder coated and oven baked finish, colour grey, with hammered texture.

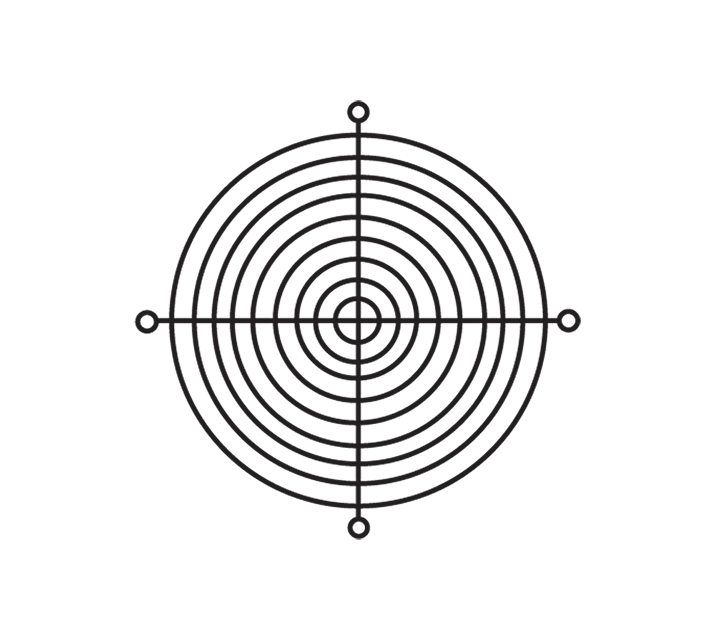

• Accident prevention and anti-bird grilles (to UNI ISO 13857 standard), consisting of electrically welded steel rings with epoxy powder coated finish, colour black.

• Centrifugal impeller with self-cleaning backward curved steel blades, hot-dip galvanized and dynamically balanced (UNI ISO 1940, Point 1 – Class 6.3), and splined steel hub.

• 1 speed three-phase AC motor, size to UNEL MEC standard, flange B5, with shaft turning in double shielded ball bearings, insulation class F.

• Cooling fan for better dissipation of heat

• Galvanized steel eye lugs for transport and lifting/handling operations.

• Cable guaranteeing continuity of earth connection.

• Steel safety wire for anchoring appliances once installed.

• Vortice speed controller.

• Aerodynamically contoured inlet port for optimum performance, fashioned as a single unit with the base and gauged to optimize air flow.

• Pressed steel motor cover: pickled and phosphated surface, polyester powder coated and oven baked finish, colour grey, with hammered texture.

• Pressed steel side baffles angled to exhaust extracted air upwards: zinc-coated, pickled and phosphated surface, polyester powder coated and oven baked finish, colour grey, with hammered texture.

• Accident prevention and anti-bird grilles (to UNI ISO 13857 standard), consisting of electrically welded steel rings with epoxy powder coated finish, colour black.

• Centrifugal impeller with self-cleaning backward curved steel blades, hot-dip galvanized and dynamically balanced (UNI ISO 1940, Point 1 – Class 6.3), and splined steel hub.

• 1 speed three-phase AC motor, size to UNEL MEC standard, flange B5, with shaft turning in double shielded ball bearings, insulation class F.

• Cooling fan for better dissipation of heat

• Galvanized steel eye lugs for transport and lifting/handling operations.

• Cable guaranteeing continuity of earth connection.

• Steel safety wire for anchoring appliances once installed.

• Vortice speed controller.

Certifications

-

CE

CE

-

EAC

EAC

Technical Data Sheet

-

Frequency (Hz)50

-

Insulation classI°

-

Max absorbed current (A)3,10

-

Max absorbed power (W)1600

-

Max ambient temperature for continuous operation (°C)75

-

Motor protection IP55

-

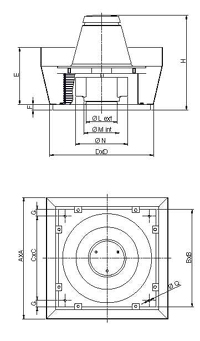

Nominal diameter (mm)550

-

Number of phases (Ph)3

-

Number of poles8

-

Voltage (V)400

-

Weight (Kg)176

-

Max airflow (l/s)4167

-

Max airflow (m³/h)15000

-

Max pressure (mmH2O)45

-

Max pressure (Pa)441

-

RPM715

-

Sound pressure Lp [dB (A)] at 3 m74

-

Dimension Q (mm)Ø 12

-

Size A (mm)1462

-

Size B (mm)980

-

Size C (mm)900

-

Size D (mm)1010

-

Size E (mm)595

-

Size F (mm)38

-

Size G (mm)40

-

Size H (mm)903

-

Size L (mm)520

-

Size M (mm)Ø 529

-

Size N (mm)Ø 805

Interested?

If you are interested in this product, contact us or locate your nearest Vortice dealer.

Documentation

You can see all the documentation relating to this product: price list, information booklet and wiring diagram.