Description

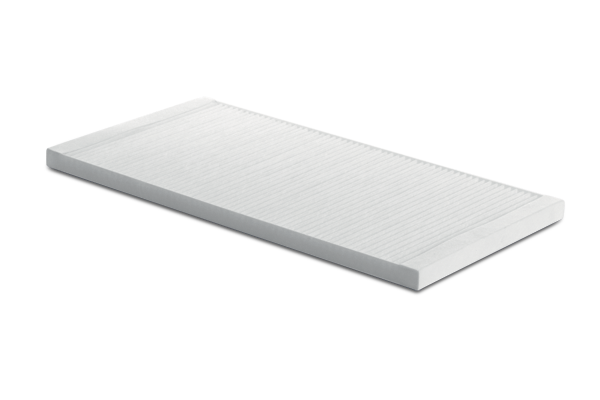

• Galvanized and painted sheet steel enclosure.

• Aesthetic front panel made of plastic resin (ABS).

• Internal components made of EPP.

• Round duct connection ports, nominal diameter 160 mm.

• 2 EC (brushless) motors, external rotor, controlled at constant airflow, with shaft turning in ball bearings to grant a “maintenance free” functioning, each coupled to a forward curved centrifugal impeller; 4 speeds, independently adjustable at the installation.

• Enthalpy heat exchanger.

• Automatic, 100% filtered, mechanic by-pass, granting people comfort in the rooms in mid-season or when the outside temperature does not require the action of the heat exchanger.

• Automatic frost-protection to prevent icing on the heat exchanger.

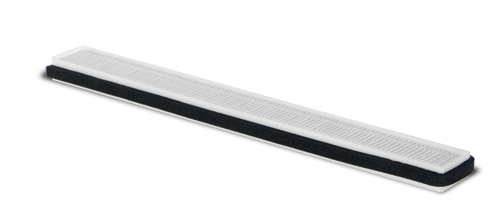

• 3 x ISO Coarse 90% (G4) filters, respectively on extraction, supply ports and for the by-pass. ePM10 50% (M5) and ePM1 55% (F7) filters available as optional per the supply port and for by-pass.

• Condense water tray with discharge pipes.

• Wired control panel with LCD display, which allows:

• to switch on / off the unit;

• the first set-up;

• to set the speed;

• to set the weekly timer;

• to monitor the correct product operation (any faults are shown on the display);

• to show the product functioning (speed set, by-pass status, defrosting activation, pre and/or post heaters activation if installed);

• to show the filters status.

• Brackets for wall-mounted installation supplied as standard.

• Possibility of connection to environmental external sensors (available as optional), for automatic functioning control.

• Possibility of integration in home automation environment through ModBus protocol.

• Aesthetic front panel made of plastic resin (ABS).

• Internal components made of EPP.

• Round duct connection ports, nominal diameter 160 mm.

• 2 EC (brushless) motors, external rotor, controlled at constant airflow, with shaft turning in ball bearings to grant a “maintenance free” functioning, each coupled to a forward curved centrifugal impeller; 4 speeds, independently adjustable at the installation.

• Enthalpy heat exchanger.

• Automatic, 100% filtered, mechanic by-pass, granting people comfort in the rooms in mid-season or when the outside temperature does not require the action of the heat exchanger.

• Automatic frost-protection to prevent icing on the heat exchanger.

• 3 x ISO Coarse 90% (G4) filters, respectively on extraction, supply ports and for the by-pass. ePM10 50% (M5) and ePM1 55% (F7) filters available as optional per the supply port and for by-pass.

• Condense water tray with discharge pipes.

• Wired control panel with LCD display, which allows:

• to switch on / off the unit;

• the first set-up;

• to set the speed;

• to set the weekly timer;

• to monitor the correct product operation (any faults are shown on the display);

• to show the product functioning (speed set, by-pass status, defrosting activation, pre and/or post heaters activation if installed);

• to show the filters status.

• Brackets for wall-mounted installation supplied as standard.

• Possibility of connection to environmental external sensors (available as optional), for automatic functioning control.

• Possibility of integration in home automation environment through ModBus protocol.

Technical Data Sheet

-

Filter class on extractG4

-

Filter class on supplyG4

-

Frequency (Hz)50-60

-

Insulation classI°

-

IPX2

-

Max absorbed current (A)2,75

-

Max absorbed power (W)350

-

Nominal current (A)1,80

-

Nominal diameter (mm)160

-

Nominal power (W)230

-

Voltage (V)220-240

-

Weight (Kg)40

-

Breakout sound power LWA [dB(A)]47,2

-

Breakout sound pressure at 3m at Max speed Lp [dB (A)]26,7

-

Max airflow (l/s)110

-

Max airflow (m³/h)400

-

Max pressure (mmH2O)69

-

Max pressure (Pa)680

-

Max thermal efficiency (%)90,4

-

Sound power at exhaust inlet LWA [dB(A)]45,7

-

Sound power at supply outlet LWA [dB(A)]61,5

-

Sound pressure at 3m at Max speed at extraction side Lp [dB (A)]25,2

-

Sound pressure at 3m at Max speed at supply side Lp [dB (A)]41,0

* Technical datas above refer to the product powered at 50 Hz.

For values for 60 Hz power supply, please contact the VORTICE Presales Service at prevendita@vortice-italy.com.

-

Size A (mm)708

-

Size B (mm)480

-

Size C (mm)730

-

Size D (mm)766

-

Size E (mm)125

-

Size F (mm)205

-

Size G (mm)516

-

Size H (mm)Ø 158

-

Size I (mm)207

-

Size J (mm)308

Interested?

If you are interested in this product, contact us or locate your nearest Vortice dealer.

Documentation

You can see all the documentation relating to this product: price list, information booklet and wiring diagram.

Energy label

Energy label